Industry Park of Shangkeng

Sanmen ,Taizhou ,Zhejiang ,China

Cold work molds are molds used for pressure processing […]

Cold work molds are molds used for pressure processing or other processing of materials at room temperature. It has a wide variety and complex structure. The mold is subjected to mechanical forces such as compression, stretching, bending, impact, and friction during use. The normal failure modes of cold work die mainly include wear, brittle fracture, bending, seizure, collapse, gnawing, softening, etc. Therefore, cold work die steel is required to have high deformation resistance, fracture resistance, and wear resistance after phase change heat treatment. Abilities such as damage resistance, fatigue resistance, and seizure resistance to ensure that the mold has a certain degree of durability.

Performance requirements of cold work molds

According to the working conditions and failure modes of the cold work die, the cold work die steel should have the following basic properties:

۞ High hardness and high wear resistance, keep sharp cutting edge when working

۞ High strength and toughness and stable thermal hardness, the blade is not easy to crack or collapse during work.

۞ Better hardenability, to ensure that the quenched state has a higher hardness and a certain depth of hardening.

۞ Better processing technology and formability, better quenching safety, small heat treatment deformation, and not easy to quench cracks on complex sections.

a. The wear resistance of the mold

When the cold work mold is working, there are many frictions between the surface and the blank. The mold must still maintain a low surface roughness value and high dimensional accuracy in this case to prevent early failure. In order to improve the wear resistance of cold work molds, it is usually required that the hardness of the mold is 30% to 50% higher than the hardness of the workpiece. The structure of the material is tempered martensite or lower bainite with uniform distribution and fine granular carbonization. Things. Therefore, the mass fraction of carbon in steel is generally above 0.6%.

b. Toughness of the mold

The toughness of the mold material should be determined according to the working conditions of the mold. For molds subjected to strong impact loads, such as punching dies of cold work molds, cold heading dies, etc., the impact load is relatively large, and high toughness is required; for general work The failure mode of the cold work mold under the conditions is fatigue fracture, so the mold does not have to have an excessively high impact toughness value.

c. The strength of the mold

The strength of the mold is the ability of the mold parts to resist deformation and fracture during the working process. Strength index is an important basis for cold work die design and material selection, mainly including: tensile yield point, compression yield point, etc. Yield is an index to measure the plastic deformation resistance of mold parts, and it is also the most commonly used strength index. In order to obtain high strength, in the mold manufacturing process, it is necessary to select the appropriate mold material, and through the appropriate heat treatment process to achieve its requirements.

d. The fatigue resistance of the mold

Cold work molds are usually fatigued under the action of alternating loads. Therefore, in order to improve the service life of the mold, higher fatigue resistance is required. The factors that lead to die fatigue include: banded and networked carbides in steel, coarse grains; small knife marks on the surface of the die, excessive changes in the size of grooves and cross-sections, and surface decarburization.

e. The seizure resistance of the mold

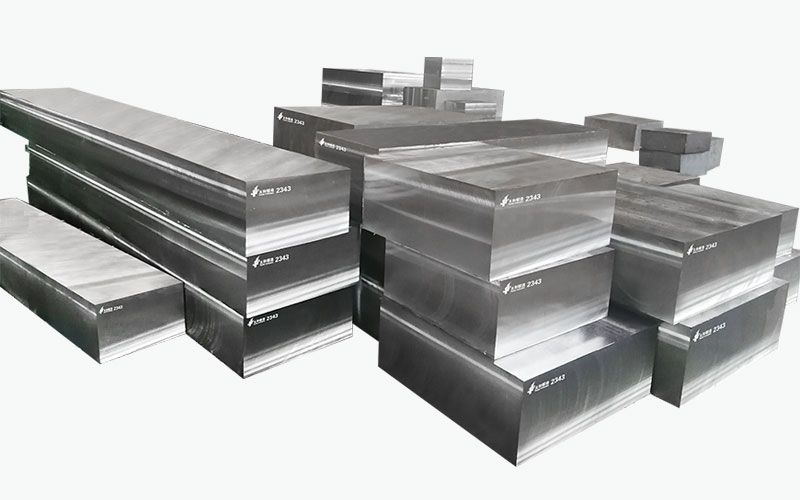

When the stamping R material comes into contact with the mold surface, the lubricant film is destroyed under high-pressure friction. At this time, the stamping metal is cold welded to the mold cavity surface to form metal nodules, thereby marking marks on the surface of the workpiece. The bite resistance is the resistance to High-strength 1.2343 Hot Work Tool Steel.