Industry Park of Shangkeng

Sanmen ,Taizhou ,Zhejiang ,China

Product Features

Characteristics

Hot work die steel with high thermal resistance and have better isotropic property than conventional melted steel.

Chemical Composition

|

Product Name |

Ingredient(Wt,% ) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| 2343 | 0.32-0.42 | 0.80-1.20 | 0.30-0.40 | ≤0.025 | ≤0.02 | 4.80-5.50 | / | 1.10-1.40 | 0.30-0.50 |

Grades Compariaon

| National Standard(GB ) | American Standard(AISI) | Japanese Standard(Jis) | German Standard(DIN ) |

| 4Cr5MoSiV | H11 | SKD 6 | 1.2343 |

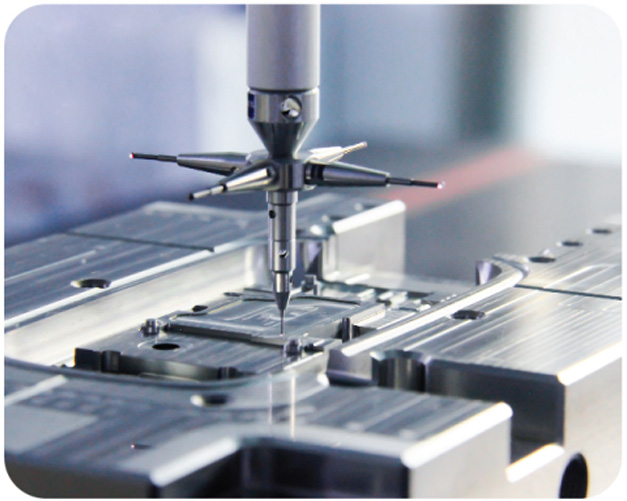

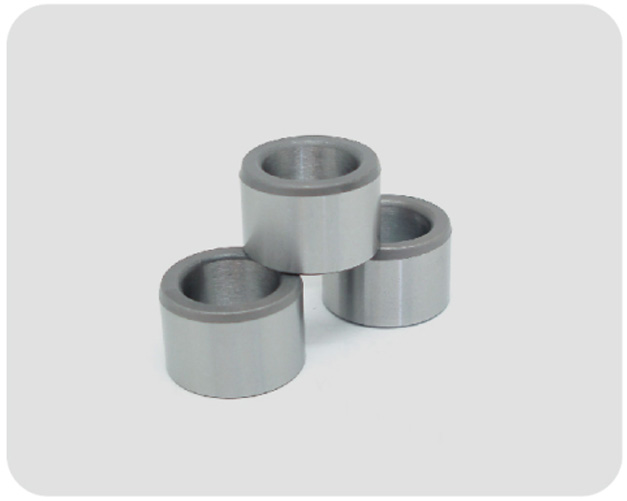

Chief Application

Die casting die, mold core, insert, thimble; extrusion die, mold core, die cushion, lining, hot pressing molding of aluminum, copper and magnesium; plastic mould, cold punching, trimming, hot shear, tightener ring and abrasive resistance.

|

|

|

| Cavity | Ejector Pin | Bush |

Physical Properties

|

Thermal Expansion Coefficient 10-6m(m*k) |

20~1 00°C | 20~200°C | 20 〜300°C | 20~500°C |

| 11 | 11.9 | 12.4 | 13 |

|

Thermal Conductivity W/m*k |

20°C | 200°C | 300°C | 700°C |

| 39.6 | 41.6 | 41.8 | 40.3 |

Metallographic Structure(Annealing)

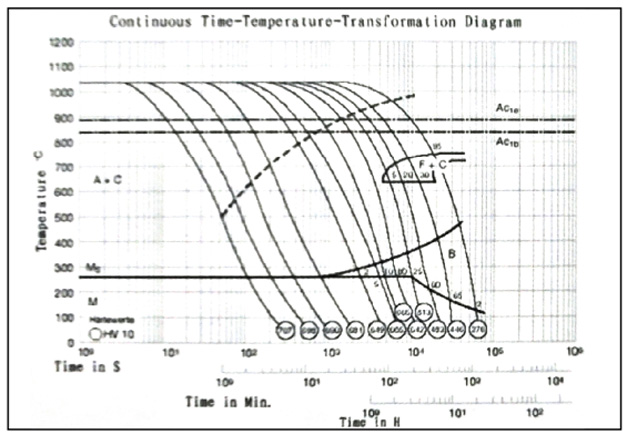

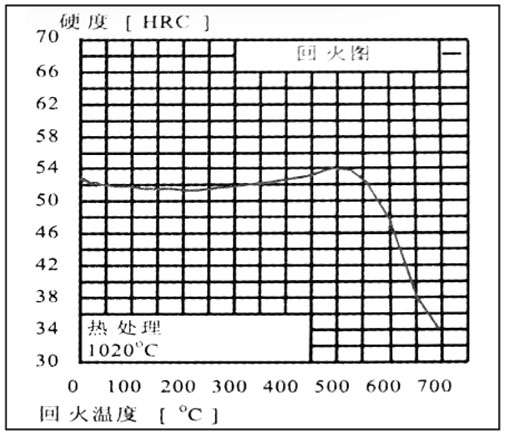

| Continuous Cooling Transition(CCT)Map | Tempering Curve |

|

|

Steel Display