Industry Park of Shangkeng

Sanmen ,Taizhou ,Zhejiang ,China

Product Features

|

|

Chemical Composition

|

Product Name |

Ingredient(Wt,% ) | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo | V | |

| P20 | 0.32-0.38 | 0.20-0.40 | 0.70-1.00 | ≤0.025 | ≤0.020 | 1.60-2.00 | / | 0.30-0.55 | / |

Specification & Hardness

Physical Properties

|

Thermal Expansion Coefficient 10-6m(m*k) |

20~1 00°C | 20~200°C | 20 〜300°C | 20~400°C | 20~500°C | 20 〜600°C | 20 〜700°C |

| 11.1 | 12.9 | 13.4 | 13.8 | 14.2 | 14.6 | 14.9 |

| Thermal Conductivity W/m*k | 20°C | 350°C | 700°C |

| 35.7 | 33.6 | 32 |

Forging

| Item | HeatingTemperature(°c) | Cool Method | Hardness |

| Annealing | 710-740 | Furnace Cold | ≤220HB |

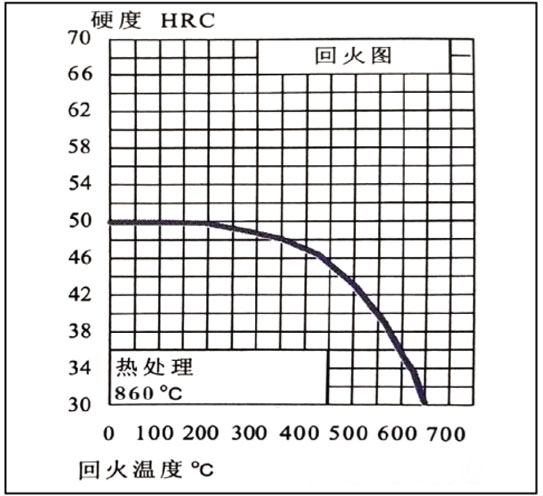

| Quenching | 840-880 | Oil Cooler | 52-55HRC |

| Tempering | 580-680 | Air Cooling | 30-35HRC |

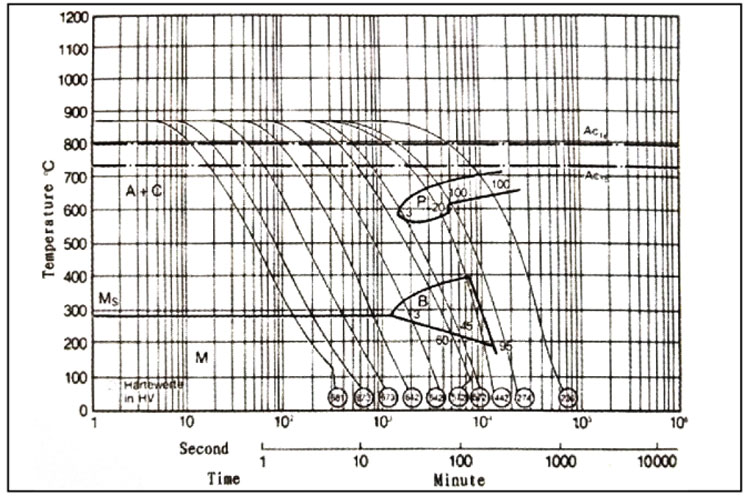

| Continuous Cooling Transition (CCT)Map | Tempering Curve |

|

|

Steel Display