Industry Park of Shangkeng

Sanmen ,Taizhou ,Zhejiang ,China

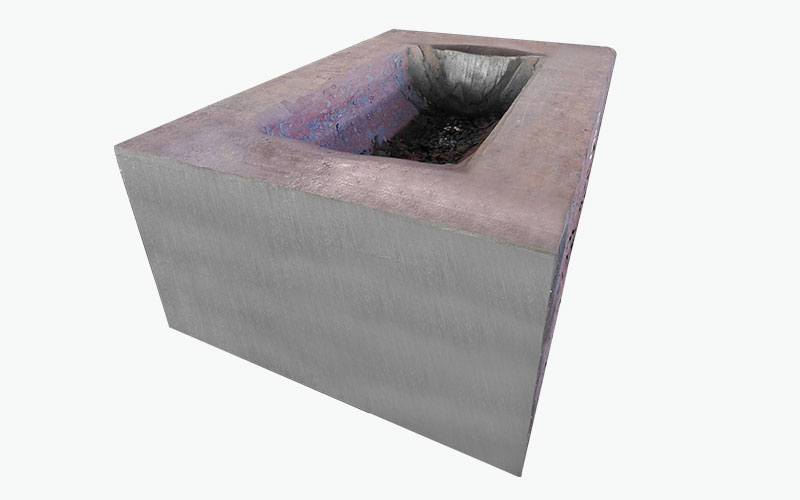

Closed Die Forging is a forging process in which dies move towards each other and covers the workpiece in whole or in part. The heated raw material, which is approximately the shape or size of the final forged part, is placed in the bottom die. The shape of the forging is incorporated in the top or bottom die as a negative image. Coming from above, the impact of the top die on the raw material forms it into the required forged form.

Closed die forging process is also referred to as impression forging. It utilizes pressure to compress the metal piece to fill an enclosed die impression. A medium frequency induction heating furnace is used to heat the metal to get the desired shapes.

Closed-die forging, or impression-die forging, involves the metal being placed in a die that contains the shape of the part. The metal is then hammered or pressed, causing the metal to flow and fill the die cavities and the shape of the part. After forging, the flash is removed.

With closed-die forging, little to no machining is needed. The process utilizes the force from the hammer or press and, often, heat in order to deform the metal to fill an enclosed die impression that contains the shape of the part.

Advantages: