Industry Park of Shangkeng

Sanmen ,Taizhou ,Zhejiang ,China

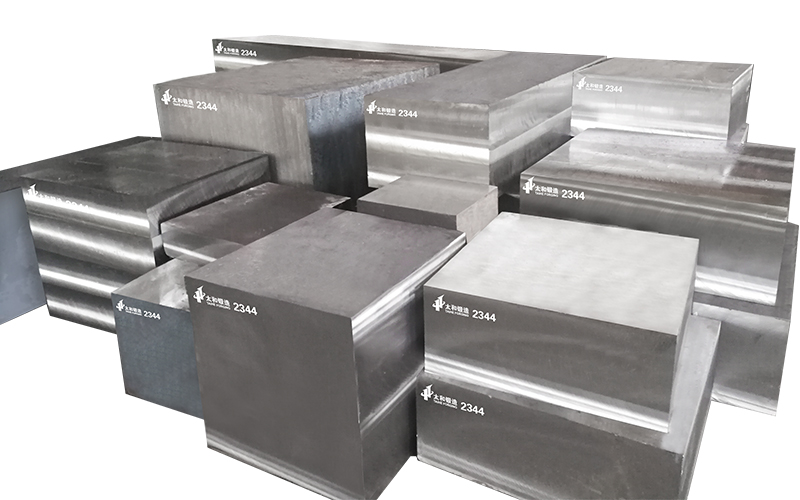

Hot work die steel refers to alloy tool steel suitable […]

Hot work die steel refers to alloy tool steel suitable for making a die for thermal deformation of metal, such as hot forging die, hot extrusion die, die casting die, hot heading die, etc. Because hot work molds work under high temperature and high pressure conditions for a long time, the mold materials are required to have higher strength, hardness and thermal stability, especially high thermal strength, thermal fatigue, toughness and wear resistance.

The hot working mold is under great impact when it is working. The mold cavity is in contact with the high-temperature metal, and it is repeatedly heated and cooled, and its use conditions are extremely bad. In order to meet the requirements of the hot work die, the hot work die steel should have the following basic characteristics:

1 High thermal stability. Thermal stability refers to the ability of steel to maintain its mechanical properties at room temperature for a long time at high temperatures. When working as a hot mold, it is in contact with hot metal or even liquid metal, so the surface temperature of the mold is very high, generally 400 to 700 ℃. This requires that the hot work die steel does not heat up at high temperature and has high thermal stability, otherwise the die will plastically deform, causing collapse and failure.

2 Excellent heat fatigue resistance. The working characteristics of the hot working mold are repeated heating and cooling. The mold expands and shrinks at once, forming a large thermal stress, and this thermal stress is generated in opposite directions and alternately. Under repeated thermal stress, a network crack (cracking) will form on the surface of the mold. This phenomenon is called thermal fatigue. Premature fracture of the mold due to thermal fatigue is one of the main reasons for the failure of the hot work mold. Therefore, hot work die steel must have good thermal fatigue.

3 High temperature strength and good toughness. Hot working dies, especially hot forging dies, are subjected to a large impact force during operation, and the impact frequency is very high. If the die does not have high strength and good toughness, it is easy to crack.

4 Good wear resistance, because in addition to the friction and wear caused by the deformation of the blank during the manufacture of the hot work die, it is also subject to high temperature oxidative corrosion and grinding of iron oxide chips, so the hot work die steel needs to have higher hardness and anti-adhesion Sex.

5 Good thermal conductivity. In order to prevent the mold from accumulating too much heat and lowering the mechanical properties, it is necessary to reduce the temperature of the mold surface as much as possible and reduce the temperature difference inside the mold. This requires that the hot work die steel have good thermal conductivity.

6 Good forming process performance to meet the needs of forming.

7 High hardenability. Hot work die steel is generally larger in size, especially for hot forging dies. In order to make the mechanical properties of the entire die section uniform, this requires that the hot work die steel has high hardenability.